-

High Strength Aluminium Alloy Plate 7075 7050 T3 T4 T6 T651 3mm 5mm 6mm 15mm

highest strength 7075 7050 T3 T4 T6 T651 3mm 5mm 6mm 15mm aluminium alloy plate for aerospace industry

7075 aluminium alloy plate is an aluminium alloy, with zinc as the primary alloying element. It is strong, with a strength comparable to many steels, and has goodfatigue strength and average machinability.

7075 alloy aluminum plate is made of one of the strongest of the aluminum alloys. Its use parallels that of 2024, with 7075 selected when higher mechanical properties are desired. 7075 aluminum is an aluminum-zinc alloy with 1%-8% zinc in addition to small amounts of magnesium and small quantities of copper and chromium.

7075-T6 Bare Aluminum alloy sheet | aluminium alloy Plate is primarily used in aerospace industry, often referred to as the Strongest Aluminum grade. Unlike the Clad, the Bare Sheet isn’t coated with an additional aluminumlayer. Alloy 7075 has the strength of many steels, while retaining aluminum’s lightweight qualities.

In terms of strength, 7075 Aluminum is near the top of the list among aluminum alloys manufactured for the needs of consumer and industrial markets. Among other 7XXX alloys, alloy 7075 exists as a standard with a solid mix of properties suitable for aircraft and aerospace applications. In particular, this alloy utilized in various forms, including as 7075 aluminum bar, is well-suited for use in parts that endure high stress levels. The strength properties of alloy 7075 are beneficial for the manufacture of items such as aircraft structures, military grade rifles, bicycle parts and equipment, and plastic industry molds.

-

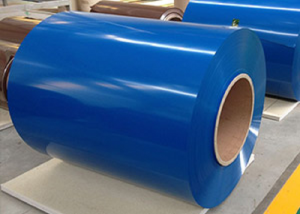

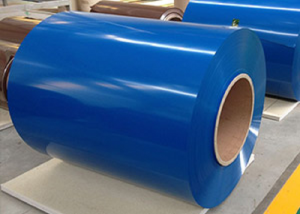

1050 3003 5052 5754 Color Coated Aluminum Coil PVDF Paints For Building Outdoor Wall Panel

1050 3003 5052 5754 color coating aluminium coil PVDF paints for building outdoor wall panel

Color Match of PVDF Coated Coil

1. For custom’ color requests, we can deal as following:Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production

Coil coating is the continuous and highly automated industrial process for efficiently coating coils of metal. Because the metal is treated before it is cut and formed, the entire surface is cleaned and treated, providing tightly-bonded finishes.

-

PE PVDF Paints Color Coated Aluminum Coil 1050 1100 3003 1060 For Roofing Sheet

Aluminum Roofing Coil is the continuous and highly automated industrial process for efficiently coating coils of metal. Because the metal is treated before it is cut and formed, the entire surface is cleaned and treated, providing tightly-bonded finishes.

Aluminium Sheet Coil

1. For custom’ color requests, we can deal as following:Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production

-

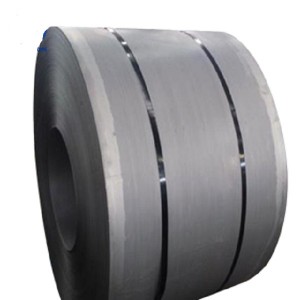

S350GD G550 dx51d dx52d z150 z140 steel building galvanized steel coils sheets DX51D Slit Coil

Galvanized Steel Sheet is defined as a carbon steel sheet coated with zinc on both sides. Galvanized Steel Coil produce galvanized steel with two main processes: continuous hot dip galvanizing and electro galvanizing.

Specifications of Galvanized Steel Coils that We Can Provide :

1) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer’s request

2) Grade: SGCC, SGCH,DX51D, Q195,Q235 all according to the customer’s request3) Capacity: about 12000 tons per month

4) Thickness: from 0.13mm to 2mm, all available

5) Width: from 600mm to 1250mm, regular size:750-762mm,900-914mm,1000mm,1200mm,1219-1250mm all available

6) Coil ID: 508mm

7) Coil weight: from 2-10MT, according to the customer’s request

8) Zinc coating weight: 40g/m2-275g/m2

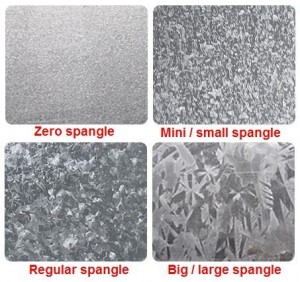

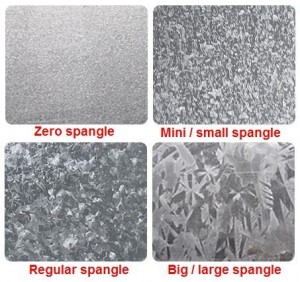

9) Spangle: regular spangle,big spangle, small spangle and zero spangle

10) Surface treatment: Chemical passivating, oils, passivating oils,skin passed

11) Edge: mill edge, cut edge

12) Min trial order 25 ton each thickness -

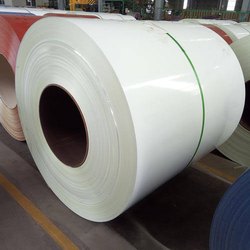

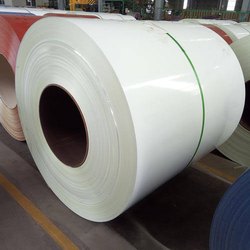

Color Coated Painted Steel Coil Corrosion Resistance EN10327 DX51D+AZ

Color Coated Painted Steel Coil Corrosion Resistance EN10327 DX51D+AZ

Painted steel coil(PPGI PPGL) usually use roll paint technique to apply different color paint on the surface of galvanize steel or galvalume steel. Customers can choose colors referring to Ral color. Ral 3005, Ral 5012, Ral 6022, Ral 9006 is the most popular color.

Prepainted steel sheet is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

-

Prime Color coated Hot Dip Galvanized Steel Coil for roofing sheet

Prime Color coated Hot Dip Galvanized Steel Coil for roofing sheet

Galvanized steel sheet /coil features:

1. Zinc coating :15-275g( as required)

2. thickness:0.16-0.6mm

3. width:600-1250mm(Standard width 914mm, 1000mm, 1215mm, 1250mm )

4. coil id:508mm-610mm(as required)

5. coil weight: 3-10 MT(as required)

6. MOQ 25ton

PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used including polyester, silicon modified polyester, high-durability, corrosion-resistance and formability

-

DX51D SGCC color coating Galvanized steel coil

PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used including polyester, silicon modified polyester, high-durability, corrosion-resistance and formability

DX51D PPGI Prepainted Galvanized Steel Coils

Standard: AISI, ASTM, BS, DIN, GB, JIS Thinckness: 0.12mm-0.8mm As to your requirements Material: Q235 Q345 Cold Rolled steel coil Grade: SGCC,SGCD,SPCC,DX51D,DX52D,DX53D Width: 600mm-1250mm Color: Red, Blue, Black, White, Gray or customized As to your requirements Substrate Cold rolled Substrate /Hot rolled Substrate Application Fields: plant,warhouse ,officebuilding, aeroshed , high-riser building etc Painting Thickness Top side: 20+5microns; Bottom side: 5~7microns. Color System Produce according to RAL Color System or as per buyer’s color sample. Painting structure Top surface Bottom surface Primer coating No coating 1/0 Primer coating Primer coating 1/1 Primer coating + Finish coating No coating 2/0 Primer coating + Finish coating Primer coating or single back coating 2/1 Primer coating + Finish coating Primer coating + Finish back coating 2/2 -

Pre-painted galvanized steel sheet coil PPGI color coated steel coils

PPGI is pre-painted galvanised iron, also known as pre-coated steel, coil coated steel, color coated steel etc., typically with a hot dip zinc coated steel substrate. The term is an extension of GI which is a traditional abbreviation for Galvanized Iron.

Using Hot Dip Galvanized Steel Coil as the substrate, PPGI is made by first going through surface pretreatment, then the coating of one or more layers of liquid coating by roll coating, and finally baking and cooling. The coatings used including polyester, silicon modified polyester, high-durability, corrosion-resistance and formability.

Standard Export Packing:

- 4 eye bands and 4 circumferential bands in steel

- Galvanized metal fluted rings on inner and outer edges

- Galvanized metal and waterproof paper wall protection disk

- Galvanized metal and waterproof paper around circumference and bore protection

About the sea worthy packaging: extra reinforcement before shipment to ensure that the goods are safer and less damaged to customers.

-

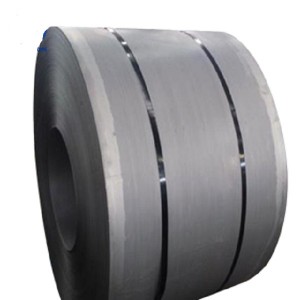

High strength tension hot rolled pickled oiled S235 S355 S420 S550 structural carbon steel slitted strip coil

High strength tension hot rolled pickled oil S235 S355 S420 S550 carbon steel slitted strip coil

S355 grade steel is a medium tensile, low carbon manganese steel which is readily weldable and possesses good impact resistance (also in sub-zero temperatures).

What is the difference between S275 and S355 steel?S275 provides a lower strength (than S355) but has good machinability and can be welded. The average minimum yield for S275 steel is 275 N/mm² giving its name: S275. S355 is often used in the most demanding environments such as the offshore industry.EN10149 S420MC steel plate/sheet,EN10149 S420MC steel plate/sheet, under EN standard, we can regard S420MC steel plate/sheet as high yield strength steels for cold-forming steels.

S420MC steel plate is mainly used as high yield strength steels for cold-forming steels.

The EN10149 S420MC steel is equivalent to SEW092 QStE420TM, NFA E420D, UNI FeE420TM, ASTM X60XLK and BS HR50F45 steel grades.

S420MC EN 10149-2 Number:1.0980 Comparision of steel grades SEW092 QStE 420TM NFA36-231 E420D UNI8890 FeE420TM ASTM 060XLK BS1449 HR50F45 -

China Prime G30 G60 G90 Hot Dipped Galvanized Steel Coil/ Gi Steel Coil / HDG Zinc Coating Roll Manufacturer

China Prime G30 G60 G90 Hot Dipped Galvanized Steel Coil/ Gi Steel Coil / HDG Zinc Coating Roll Manufacturer

Name Galvanized steel coil Grade DX51D+Z, DX52D+Z, DX53D+Z, DX54D+Z, DX56D+Z, DX57D+Z, DC51D+Z, SGCC, SGCD,S220GD+Z, S250GD+Z, S280GD+Z, S320GD+Z, S350GD+Z, S550GD+Z Width 600-1500mm Thickness 0.12-4mm Zinc coating 30-275/m2 Surface treatment chromed / oiled/slightly oiled/ dry Hardness soft, full hard, half hard Spangle zero spangle / minimized spangle / regular spangle/ big spangle ID coil 508mm or 610mm Coil weight 2-8 MT per coil. According to the customer’s requirements Package: Standard export package (Plastic film in the first layer,second layer is Kraft paper. Third layer is galvanized sheet) Application: Industrial panels, roofing and siding for painting Applications of Our Galvanized Steel Coils :

1.Construction and building: roofing; ventilating duct; handrail; partition panel,etc.

2.Further processing: coating base plate.

3.Electric appliance: refrigerator; washing machine; recorder; microwave, etc.The hot dip process includes passing the steel through a molten zinc bath, and the electro galvanizing process includes applying zinc through electrolytic treatment. As a result, the zinc layer is firmly adhered to the base metal through the iron-zinc bonding layer. Our hot-dip galvanized products are manufactured in accordance with specifications, and our electro-galvanized products comply with the specifications.

Galvanizing is one of the most effective and economical methods for protecting bare steel from corrosive environments. Zinc is not only a barrier between steel and the environment, but also sacrifices itself to protect the steel plate below. When two different metals are in contact and coupled with water and oxygen, sacrifice or current protection occurs. Zinc preferentially corrodes iron in steel. This protection prevents corrosion of the steel in areas not covered by zinc. Therefore, the diffusion of corrosion from cutting edges, drilling holes, etc