-

black anodized aluminum sheet Bronze anodized aluminum plate

Anodizing is an electrolytic process that vastly increases the thickness and toughness of this aluminum oxide layer

Black dye is one of those dyes that are formulated especially for coloring aluminum. The dye is absorbed by the porous anodic coating. The more dye that is absorbed the deeper the color and the longer it will hold its color depending on what color it is

Black Anodizing Black anodizing is a process through which the surface of an anodized metal is dyed black. Before the sealing stage of anodizing, the oxide surface of a metal can be dyed. This is done when the exterior appearance of the product is significant.

Anodized aluminum is ideal for a wide range of construction and architectural applications. Notably, anodized aluminum colors will never chip, peel, or fade in sunlight, making them popular for many commercial, industrial, and consumer applications. Common applications include construction components for building exteriors, vents, window frames, doors, and other structural applications.

Not all aluminum alloys can be anodized successfully. Different aluminum alloys contain different types and amounts of alloying metals, which produce coatings of different properties, some of which are less desirable

-

aluminum checker plate anodized black color aluminum tread plate

Black aluminum tread plate also known as diamond plate or checker plate.

Black aluminum tread plate that has non-stamped preformed treads. Made of an aluminum / manganese alloy,Black aluminum tread plate is used as scuff (kick) plates, running boards, mud flaps and more. It cuts cleanly, leaving a smooth edge. Tread plate’s protective treads also help maintain its good looks and make it easy to keep clean.

- Al metal alloy: 1000, 3000, 5000, 6000 series

- Alu temper: O – H112, T3 – T8, T351 – T851 etc

- Pattern: 1 bar, 2 bars, 3 bars, 5 bars etc

- Type: plate, roll ( coil )

- Width: 900mm – 1600mm

- Length: 800mm – 8000mm

- Thickness: 0.8mm – 10mm

Technology: hot rolled ( DC ), cold rolling ( CC ), cast Standard: ASTM B209, GB/T 3880, EN AW, DIN, MSRR, AMS, JIS, AISI, BS etc

Custom serivce: acceptable ( OEM, ODM etc )

Port of Loading: Qingdao, Shanghai, Guangzhou etc China main port

Certifications: GB/T19001-2016/ISO9001:2021, CE, SGS etc

Featuring our top-quality black aluminum tread plate that has a semi-gloss black coating with PVC protection. It is highly suitable for many practical and decorative applications including floors, walls, trailers, garages, gyms, and more.

Our black aluminum tread plate sheets are pressed aluminum sheets bearing a raised tread pattern on one side and are then coated in semi-gloss black for an edgy, modern look. tread plate is also called tread plates, checker plates, and/or durbar plates.

-

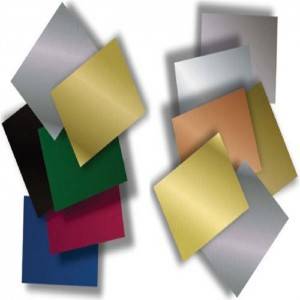

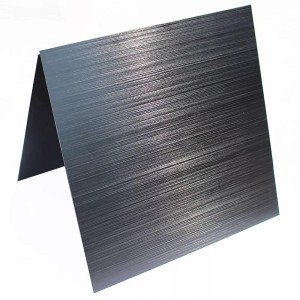

China brushed anodized aluminum sheet copper color anodising black aluminium plate

China brushed anodized aluminum sheet copper color anodising black aluminium plate

Anodized aluminum sheet is a sheet metal product consisting of aluminum sheeting exposed to an electrolytic passivation process that imparts a tough, hard-wearing protective finish on its surface. The protective layer formed by the anodizing process is actually little more than an enhancement of the natural oxide layer that exists naturally on the surface of the aluminum.

The aluminum plate of the anode is oxidized, and a thin layer of aluminum oxide is formed on the surface, the thickness of which is 5-20 microns, and the hard anodized film can reach 60-200 microns. The anodized aluminum plate has improved its hardness and abrasion resistance, up to 250-500 kg / mm2, good heat resistance, hard anodized film melting point up to 2320K, excellent insulation, and breakdown voltage 2000V, which has enhanced the anti-corrosion performance. It will not corrode for thousands of hours in ω = 0.03NaCl salt spray. There are a large number of micropores in the thin layer of the oxide film, which can absorb various lubricants, which is suitable for manufacturing engine cylinders or other wear-resistant parts.

-

1050 1060 6061 5052 anodized Aluminium sheet Coil

1050 1060 6061 5052 anodized Aluminium sheet Coil

Anodized aluminum sheet is a sheet metal product consisting of aluminum sheeting exposed to an electrolytic passivation process that imparts a tough, hard-wearing protective finish on its surface. The protective layer formed by the anodizing process is actually little more than an enhancement of the natural oxide layer that exists naturally on the surface of the aluminum.The aluminum plate of the anode is oxidized, and a thin layer of aluminum oxide is formed on the surface, the thickness of which is 5-20 microns, and the hard anodized film can reach 60-200 microns. The anodized aluminum plate has improved its hardness and abrasion resistance, up to 250-500 kg / mm2, good heat resistance, hard anodized film melting point up to 2320K, excellent insulation, and breakdown voltage 2000V, which has enhanced the anti-corrosion performance. It will not corrode for thousands of hours in ω = 0.03NaCl salt spray. There are a large number of micropores in the thin layer of the oxide film, which can absorb various lubricants, which is suitable for manufacturing engine cylinders or other wear-resistant parts.

Anodized aluminum plate is widely used in machinery parts, aircraft and automobile parts, precision instruments and radio equipment, building decoration, machine housing, lighting, consumer electronics, crafts, household appliances, interior decoration, signage, furniture, automotive decoration and other industries

Anodized aluminum is created through an electro chemical process which allows the color to penetrate the pores of the aluminum, resulting in an actual change in the color of the metal surface. Anodized aluminum is harder and more resistant to abrasion and corrosion.

-

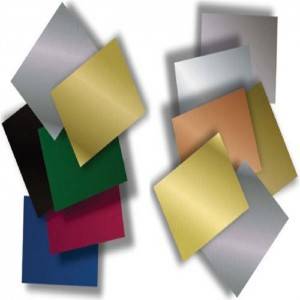

Golden Brushed Anodised Aluminum Sheet

Anodized Aluminum is corrosion and abrasion resistant meaning it will not fade, chip, peel, or flake. Anodizing is a process used to increase the thickness of the natural oxide layer on the surface of metal parts. It increases corrosion and wear resistance, and during the process the anodized aluminum surface can be dyed into many different colors.

Anodized aluminum is created through an electrochemical process which allows the color to penetrate the pores of the aluminum, resulting in an actual change in the color of the metal surface. Anodized aluminum is harder and more resistant to abrasion and corrosion. Lasers to white-ish / gray. Please note: only one side is prime and mask-protected.

Most anodized aluminums are colored on both sides and can be rotary, diamond drag, or laser-engraved. Laser engraving produces a whitish gray mark. Anodized aluminum is not recommended for sublimation. Our colored anodized aluminum is typically used in decorative applications and is not suitable for outdoor use. However, our satin silver anodized aluminum can be used outdoors. -

Anodized bronze brushed aluminum sheet

On the basis of above classification of aluminium alloys, aluminum plates can also be divided into many types. The first important principle is aluminum plate material.

1050 1060 6061 5052 anodized Aluminium sheet Coil

Anodized aluminum sheet is a sheet metal product consisting of aluminum sheeting exposed to an electrolytic passivation process that imparts a tough, hard-wearing protective finish on its surface. The protective layer formed by the anodizing process is actually little more than an enhancement of the natural oxide layer that exists naturally on the surface of the aluminum